Effective packaging is a secret that keeps businesses alive in thousands of existing industries. Shrink wrap machines are key to this, offering a reliable way to keep products tightly closed for both transit and store. The machines also serve the dual purpose of not only shielding the goods from environmental factors but also enhancing their presentation to make them more attractive to consumers.

The needs and scales of operation for the use of such shrink wrap machines call for different types. There is a shrink wrap machine designed to suit every packaging need, from small businesses with the need for manual machines to huge enterprises with fully automatic machines. Understanding the benefits and workings of such machines can save a great deal of time, as well as other resources, for businesses in the long term.

Shrink wrapping can be done in numerous ways, along with applying shrink wraps and other types of shrink wrap machines available in the market. Then, we give you insight into the key features that a person should consider when choosing the machine and some of the best models of the best manufacturers in the market. Towards the end of this article, you will fully understand how to have the right shrink-wrap machine and how to get the most out of your packaging operations.

What is Shrink Wrapping?

Shrink wrapping involves the encasing of products inside a polymer plastic film, which will be shrunk tightly around them by the application of heat. It therefore creates a sealed, protective layer that holds an item in place and is even tamper-evident.

Uses

Shrinkwrapping is versatile and widely used across various industries. For example, food manufacturers use it to keep products fresh and safe. Electronics companies rely on it to protect gadgets from dust and moisture. It is used in retail to pack goods together for easier handling and more appealing bundles to customers.

Benefits

The benefits of shrink-wrapping are many: it is excellent against environmental factors such as dust, moisture, and temperature change; secondly, it enhances the appearance of products in a clean, professional manner; and finally, it extends the life of perishable goods, delivering them to consumers in the best possible manner.

Types of Shrink Wrap Machines

Now that we are clear on what shrink wrapping is and the advantages of its application, let us consider the types of best shrink wrap machines on the market. Each of the mentioned types is unique and features certain peculiarities suitable for specific needs and volumes of packaging.

Manual Shrink Wrap Machines

Manual shrink-wrap machines are great for small businesses or very low-volume packaging needs. These machines require more hands-on involvement, as the operator manually wraps film around products before applying the heat. Although additional labor is required, the machines are quite affordable and easy to use, thus making them a good choice for startups or small-volume packaging jobs.

Semi-Automatic Shrink Wrap Machines

The semi-automatic machines of the wrappings fall somewhere between the manually operated and completely automatic models. They mechanize part of the work but retain some human intervention. They are perfect for medium-sized operations to improve efficiency without huge investments.

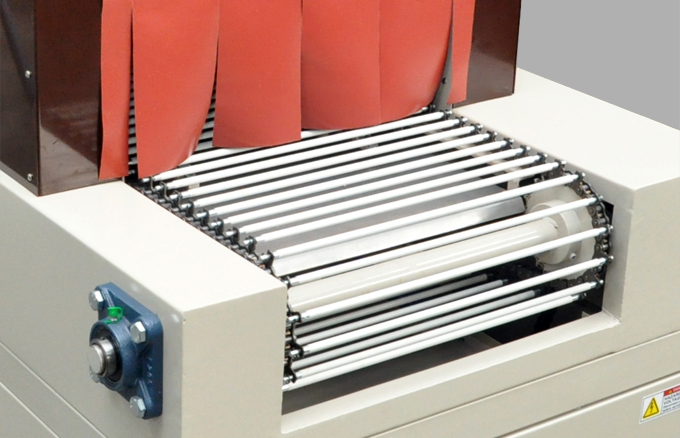

Fully Automatic Shrink Wrap Machines

They are run automatically, without the need for an individual, in that they undertake the process—from wrapping to sealing and then shrinking—thus minimizing human labor. Although they would demand some high initial installation costs, in the long run, they pay in terms of productivity and efficiency, making them cost-effective.

Key Features to Consider

Several factors will most likely come into play when deciding which shrink-wrapping machine to buy. Here are the key features to consider:

Speed and Efficiency

How fast can the machine wrap and seal products? In a high-demanding environment, this factor takes importance. A faster machine can boost the productivity level many times over, hence responding to your customers in time.

Size and Versatility

While many machines can wrap a lot of product sizes and shapes, some have limitations. Ensure the machine you purchase is suitable for your individual packaging needs.

Ease of Use

A user-friendly machine is important for smooth running. Features could include user-friendly controls, easy loading mechanisms, and straightforward maintenance requirements. An easily operable machine will save on training time and reduce errors to a minimum.

Cost

While the initial cost has to be considered, weigh the long-term benefits and possible ROI. The expensive machine might offer more efficiency and durability, therefore saving you money in the long term.

Durability and Reliability

Putting your money into a solid, reliable machine will assure you of consistent output and fewer chances of downtime. Look for quality machines constructed from quality materials and supported by quality warranties and customer service.

How to Choose the Best Shrink Wrap Machines

Choosing the right shrink-wrapping machine for your business may sound a bit big. The simple consideration of a few key factors will put you in a position to make the right decision based on your needs and your wallet. Let's break it down:

Assess Your Needs

First and foremost, evaluate your packaging volume and product types. Are you packaging small batches or large quantities? What sizes and shapes are your products? A small business might find a manual shrink wrap machine sufficient, while a large operation could benefit from a fully automatic machine.

Questions to Consider:

- How many products need to be wrapped per day?

- Are your products uniform in size, or different?

By understanding what your specific requirements are, you will be able to narrow down the options and find a machine that fits your operation.

Budget Considerations

Next, consider your budget. Sure, it's tempting to go for the cheapest option, but weigh that against more advanced machines and their long-term benefits. Higher up-front costs may pay dividends in efficiency and durability down the road.

Tips:

Estimate the possible return on investment made.

- Consider not only the purchase price but also maintenance costs and expected lifespan.

- Invest wisely in a shrink-wrap machine to boost your productivity and reduce packaging time. This will offer great savings over time.

Space Availability

Do you have space to accommodate the machine? First, measure your available workspace and ensure the machine you choose will be well accommodated without interrupting other operations.

Key Points:

- Measure both the machine and your available space.

- Consider the workflow and ensure the machine does not cause bottlenecks.

Future Scalability

As your business grows, so do your packaging needs. Opt for a machine with which you can scale. Investing in a higher-capacity machine will save you the need for an upgrade in no time.

Questions to Think About:

- What are your growth projections?

- Will the machine still meet your needs in five years?

This ensures that your investment will be rewarding, even as your business grows.